OK2000 INDUSTRY CONVEYORS:

1. Drop-off application at the top of the conveyor:

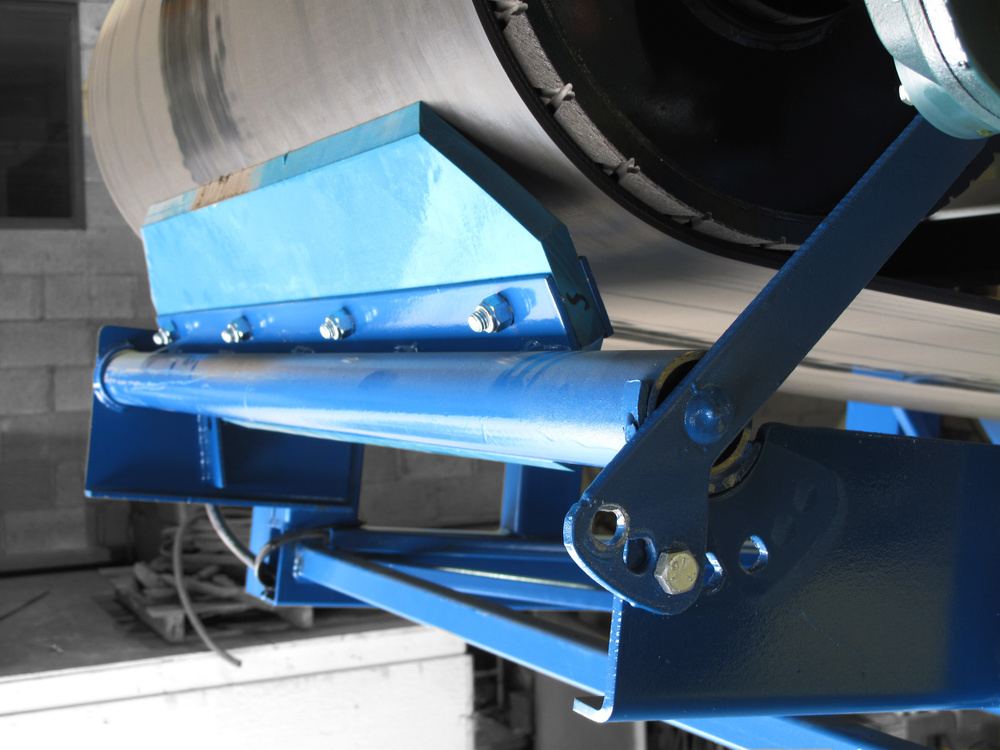

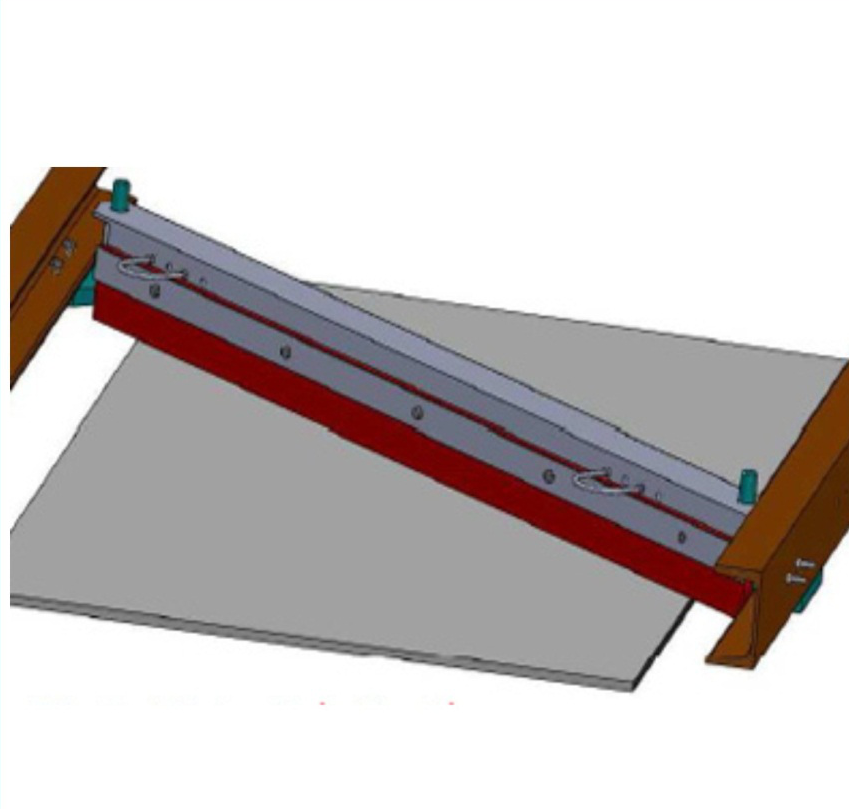

The OKULEN® IMPACT-BEDS reduces the impact energy of the material at the beginning of the conveyor belt, so that the buffer protects the belt and the conveyor belt from scratching and breaks due to the material's sharp edges. Directly onto the tape. By special production technology that 3 layers of material: OK2000 plastic, rubber cling together to form an indispensable support bar.

Excellent abrasion resistance of the OK2000 on the surface makes the material easy to slide down the conveyor, the middle material helps the damper and the bottom layer fixes the bar down to the fixed frame.

Basic bar size:

Medium load: 1200x100x75mm

Light weight: 1200x100x50mm

Other sizes are manufactured according to customer specific requirements.

In case of transportation of explosive substances with anti-static requirements, the three layers of material will be replaced with the type of impregnated carbons, ensuring the surface resistance and volume resistance of all three types of <10 ^ 5 Ω x cm.

Installation location:

Conveyor belt

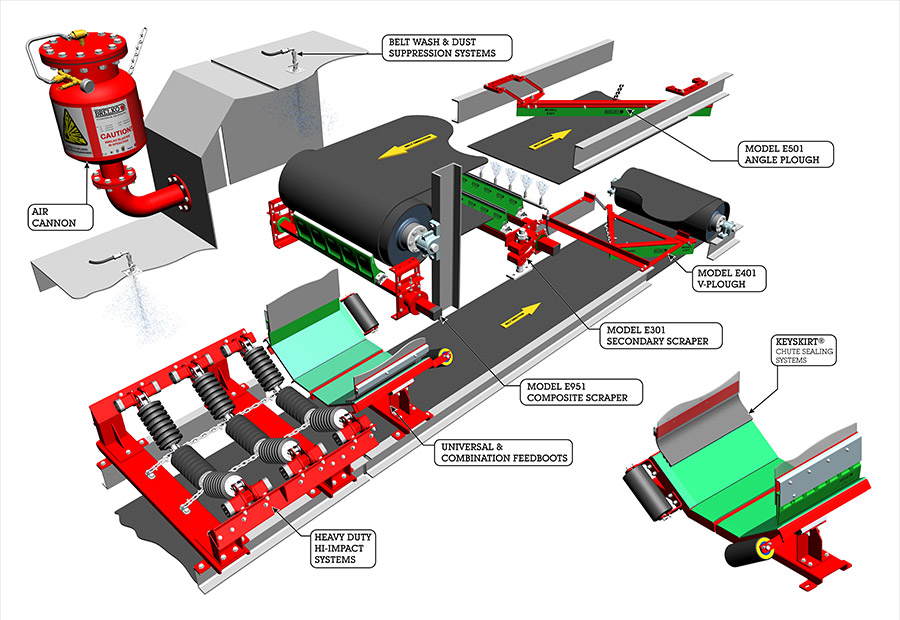

Ice goggles are used in the following locations

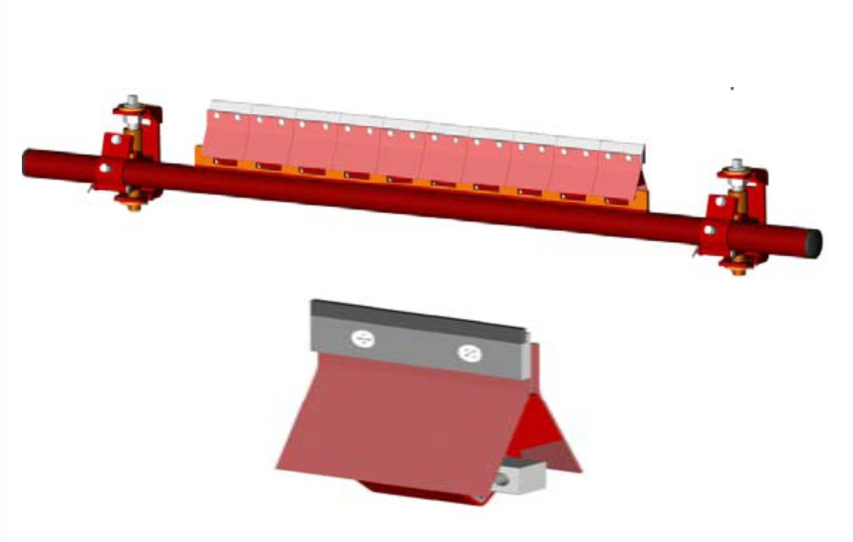

2.1 Graduated scraper at the end of the conveyor

DETAILS

Advantages

+ PU blades

+ Coefficient of friction is small

+ Good wear resistance

+ Conveyor-friendly: more efficient cleaning without harming the tape surface, especially steel cable conveyor

+Suitable for mechanical clamping tapes

Characteristic

The blade is more adaptable thanks to the modular structure. When the tape is worn by the material, showing uneven wear, the blade remains in contact with the tape profile.

Automatic Spring Compensation Compensation and Impulse Absorption:

+ Keep the optimum blade / tape contact pressure in place

+ Increase the life span of the blade

Modular design of the blade:

+ Removable and fixed by means of fixing, without bolts

+ Convenient for maintenance and replacement, especially when the needles are adjusted flat and straight

An intuitive blade pressure indicator indicates the pressure of the blade / tape face contact at any time for timely and effective adjustment.

Secondary shears

Characteristic:

1. The design has patented the blades with the clamping force of the torsional force of special plastic OK1000:

The blade is clean in a much safer way for the ice sheet. Common blades can not completely rupt material on rough conveyors, damaging the ice by adjusting the contact blade closer to the ice surface. Thanks to the spring clamping force, the OK1000 plastic has a sliding friction coefficient with a low surface, and the tongue is able to effectively remove the material on the damaged or rugged surface of the tape and thus increase its age. face ice

The unique twist system added to both sides of the bracket is designed to integrate with individual blade modules. When the external force is greater than the blade torque, the double helical system will operate and keep the blade pressure stable, providing optimum cleaning performance.

3. Easy to install and maintain thanks to the blade module design.

4. Suitable for materials: cold concrete, cement, coal, slag, salt, iron ore, fertilizer ...

2.3 V cutters

DETAILS

+ Installation location: Clean the underside of the tape in front of the passive block

+ Scrapping material, to avoid trapped fruit, broken tape

+ Hanging: easy adaptation, stable contact with the conveyor belt due to the weight of the swing V

+ Blade is PU resin, easily replaced by friction joint

+ The structure is hot galvanized: durable

2.4 Cross cut

DETAILS

+ Installation location: Clean the underside of the tape in front of the passive block

+ Scrapping material, to avoid trapped fruit, broken tape

Cross design: cleaning from both sides

+ Blade: OK1000 is abrasion resistant, easily replaced by friction joints

+ The structure is hot galvanized: durable